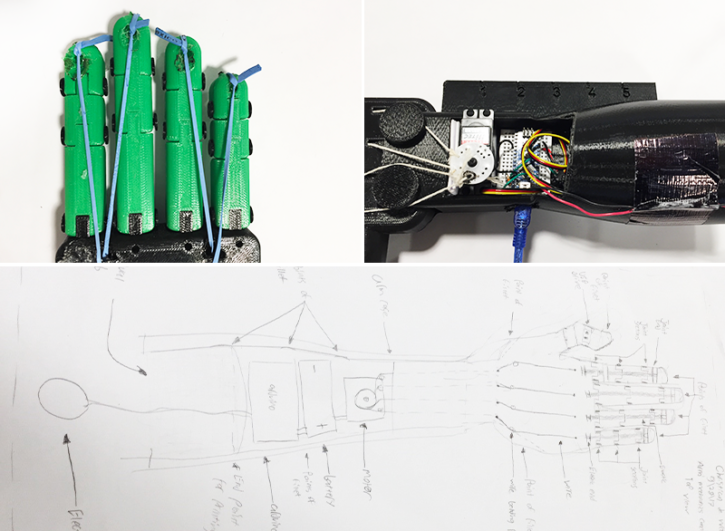

This past fall term, Christian de Weck ’19 did an independent study where he designed and 3D-printed a prosthetic arm. He presented his final product at LearnLaunch 2018 in early February. Learn more about his project – and the inspiration behind it – below.

What inspired you to create a prosthetic arm?

My inspiration for this came from a few things. The first of these was that I had a strong desire to create an object to help people in school with management and materials. I initially thought this object would be some sort of arm band that you would wear that contained all the items you might need for school. This might have included a pencil, paper, scissors, and so on. My inspiration then became more specific when I came upon this video talking about prosthetic arms for children. After watching this and doing a little bit more initial research, I came upon the realization that I could combine these two ideas into one: I could make a prosthetic arm that could help children with school. Using Beaver’s new R+D Center to complete my project, I believed I could fix the problem in prosthetics described in this video.

What makes your product better than what currently exists on the market?

What makes my prosthetic arm “better” than what is currently out there is that it’s under $300, it’s 3D-printed, and it has many attachments.

Because of the price, most people would be able to afford it, which is a much better alternative to current functional arms on the market that cost thousands of dollars. It may not have as much functionality as a thousand dollar arm, but it’s affordable.

In addition, because the arm is almost completely 3D printed, it is easy to customize and personalize, making it more appealing to everyone. Individuals can choose what they want it to look like and do. The attachments I added (the thumb drive and the straight edge) are also something that has never been on a prosthetic arm before. These attachments can give individuals an advantage in school and make day-to-day tasks easier. The current prosthetic arms out there do not have modules where you can add things that are not normally found on a human arm.

What’s something you learned that surprised you in the development of your product?

One thing that surprised me in the development of this project was the large amount of time it takes to design something from scratch. I modeled all the of the separate parts of the arm in Fusion 360, but I did not take any measurements from other files. I often had to go back and redo entire parts or start over because something didn’t work. In this process I learned so much. I became a lot more skilled in CAD, I learned how to use Arduino a lot better, and I learned about the process of creating a product.

If you were to go back and start over, what would you change?

If I were going to go back and start over, I would probably make a lot more rough drafts of my design and print those out first so I could see how things fit together.